As global plastic restriction policies tighten and consumers demand more sustainable options, food manufacturers are increasingly turning to eco friendly packaging solutions. RPET packaging has emerged as a standout choice, blending environmental responsibility with the practical needs of food storage and transportation. Hengmaster, a leading food packaging manufacturer based in Zhejiang China, has been at the forefront of this shift, producing high quality RPET plastic containers tailored for fresh food, cakes, meat, and other perishables. With a focus on safety, innovation, and sustainability, Hengmaster’s RPET packaging addresses the core challenges of food manufacturers while aligning with global green trends. Below we explore the key reasons behind RPET’s rising popularity and how Hengmaster’s offerings meet industry demands.

Environmental Compliance Drives RPET Adoption

One of the primary drivers of RPET packaging’s popularity is its alignment with global environmental regulations. Countries like China and the EU have implemented strict plastic bans, pushing food manufacturers to adopt recyclable and sustainable packaging. RPET, made from recycled polyethylene terephthalate, reduces reliance on virgin plastic and minimizes carbon footprint—critical for manufacturers aiming to meet corporate sustainability goals and avoid regulatory fines. Hengmaster’s RPET plastic containers are designed to be fully recyclable, supporting the reduce reuse recycle framework. For manufacturers packaging meat, cakes, or fresh produce, this means choosing a solution that is both eco friendly and compliant with international standards. As a Zhejiang based manufacturer, Hengmaster leverages local production capabilities to produce RPET packaging that meets the sustainability requirements of markets across Asia, South America, North America, and Europe.

BRC and FDA Certified Safety for Food Contact

Safety remains non negotiable for food packaging, and RPET’s popularity is boosted by its ability to meet strict food safety standards when produced correctly. Hengmaster’s RPET plastic containers hold BRC certification and pass FDA testing, confirming they are safe for direct contact with food. This is especially important for manufacturers handling perishables like raw meat and delicate items like cakes, where packaging contamination risks spoilage and health concerns. RPET’s inherent stability prevents chemical leaching, even in varying temperatures, ensuring the quality and safety of stored food. Hengmaster’s commitment to safety is further reinforced by its 200m² laboratory, where every batch of RPET packaging undergoes rigorous testing. For food manufacturers, this dual certification and strict quality control mean peace of mind, knowing their products are packaged in materials that protect both consumers and brand reputation.

100K-Class Clean Workshop Ensures Hygienic Production

The production environment directly impacts the quality of food packaging, and RPET’s popularity is enhanced when manufactured in sterile conditions. Hengmaster’s production base in Zhejiang China features a 3000m² 100K-class clean workshop that meets GMP standards, ensuring all RPET plastic containers are produced in a contamination free setting. Spanning 13000m² of total building area with 6000m² of dedicated storage space, the facility controls dust, microbes, and pollutants throughout the production process—from raw RPET material processing to blister forming and injection molding. This hygienic production is critical for food manufacturers, as it eliminates the risk of packaging related contamination that can ruin batches of meat, cakes, or fresh food. With advanced equipment including automatic PET PP sheet making machines and precise injection machines, Hengmaster ensures consistent quality in every RPET container, making it a reliable choice for manufacturers prioritizing hygiene.

Free Customization Meets Diverse Food Packaging Needs

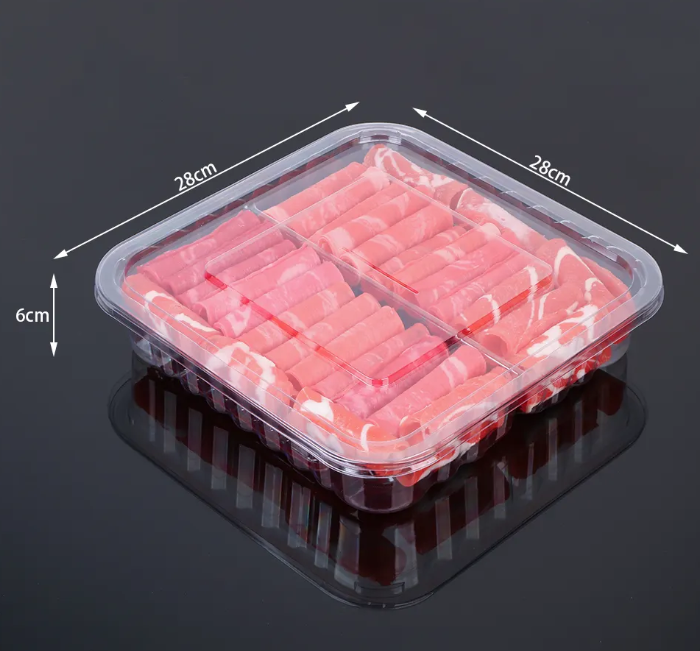

Food manufacturers handle a wide range of products, each with unique packaging requirements—from large meat trays to small cake containers. RPET’s versatility, combined with Hengmaster’s free customization services, makes it an ideal solution for these diverse needs. Hengmaster’s team of 10 technical managers collaborates with clients to design RPET plastic containers tailored to specific products: drainage channels for meat to collect excess juices, airtight seals for cakes to lock in freshness, or stackable designs for efficient storage. The company’s large scale production capacity, with an annual output of 5000 tons, enables the fulfillment of both small batch and large scale customized orders. Whether a manufacturer needs transparent RPET trays to showcase fresh produce or tamper proof containers for baked goods, Hengmaster’s customization capabilities ensure the packaging fits functional and branding needs. This flexibility has made RPET packaging a go to choice for manufacturers seeking tailored, sustainable solutions.

12-Hour Response and Timely Delivery Support Smooth Operations

In the fast paced food industry, efficiency in supply chains is crucial, and RPET packaging’s popularity is further boosted by reliable manufacturing partners like Hengmaster. The company guarantees a 12 hour response to client inquiries, ensuring manufacturers can quickly address questions about RPET specifications, customization progress, or order status. This rapid communication eliminates delays and keeps production schedules on track—essential for manufacturers dealing with perishable goods. Additionally, Hengmaster’s streamlined logistics and strategic location in Zhejiang China ensure timely delivery of RPET plastic containers. With nearly 50 employees dedicated to production and logistics, the company maintains efficient processes to meet delivery deadlines, even for international orders. For food manufacturers, this reliability means uninterrupted access to sustainable packaging, avoiding costly gaps in their supply chains.

Conclusion

RPET packaging’s rise in popularity among food manufacturers stems from its unique combination of sustainability, safety, versatility, and compliance. Hengmaster, based in Zhejiang China, has amplified these advantages by integrating its core strengths—BRC and FDA certification, 100K-class clean workshop production, free customization, rapid response, and timely delivery—into its RPET product line. Whether packaging meat, cakes, or other fresh food, Hengmaster’s RPET plastic containers meet the dual demands of environmental responsibility and practical food storage. As global green trends continue to shape the industry, food manufacturers looking to stay competitive and compliant will find RPET packaging from Hengmaster to be a valuable investment. By choosing sustainable, safe, and tailored RPET solutions, manufacturers can enhance their brand reputation, reduce environmental impact, and meet the evolving needs of consumers worldwide.