In the dynamic world of custom food packaging, the choice of raw material is the foundational decision that dictates the final product's quality, clarity, durability, and suitability. Pet sheet rolls serve as the essential starting point for creating a vast array of customized trays, clamshells, and containers. However, not all pet sheet rolls are created equal. Selecting the ideal roll requires a keen understanding of technical specifications, intended application, and the manufacturing capabilities of the supplier. For businesses aiming to develop distinctive and functional packaging for fresh foods like cakes, meats, and ready to eat meals, this selection process is critical. Hengjiang, a premier manufacturer located in Zhejiang, China, stands as a key partner in this process, offering expertly produced pet sheet rolls and end to end packaging solutions that empower brands to realize their custom packaging visions.

Understanding Pet Sheet Roll Specifications

The journey to ideal custom packaging begins with comprehending the core attributes of the pet sheet roll itself. These specifications directly translate into the performance and appearance of the final package.

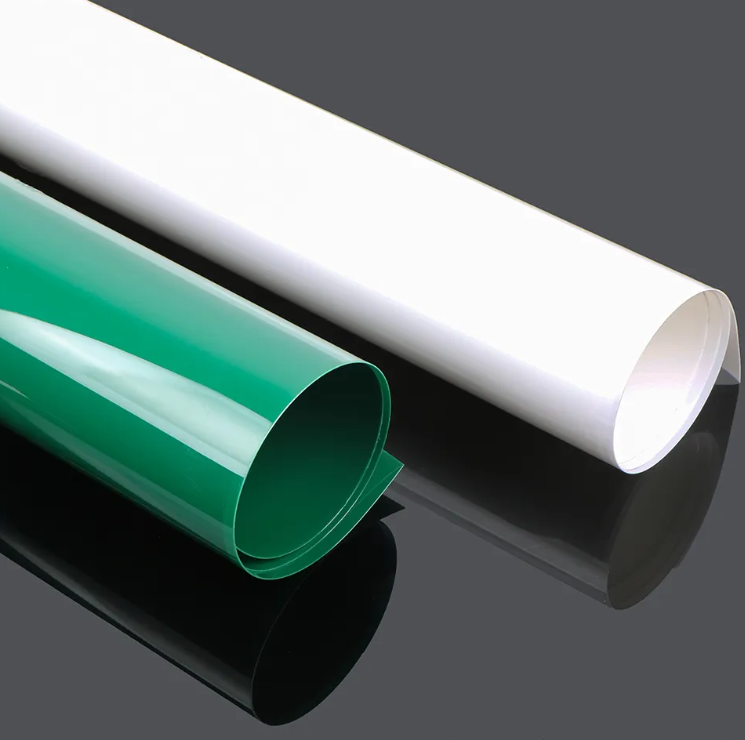

Material Grade and Clarity

The primary distinction lies in the type of PET used. Amorphous PET (APET) offers brilliant clarity and high gloss, making it perfect for packaging where product visibility is paramount, such as displaying gourmet cakes or fresh meat cuts. Crystallized PET (CPET) provides a more opaque, white finish and can withstand both freezer and oven temperatures, ideal for ready to eat meal trays. The ideal pet sheet roll must match the visual and functional demands of the product. Hengjiang’s production, utilizing automatic PET sheet making machines, ensures precise control over the material formulation, delivering rolls with consistent optical properties and material performance crucial for brand presentation.

Thickness and Mechanical Strength

The thickness of the pet sheet roll, typically measured in microns or mils, determines the rigidity and durability of the formed package. A thicker sheet yields a more robust tray suitable for heavy cuts of meat or products requiring superior crush resistance. Thinner sheets may be chosen for cost effective, lightweight packaging for bakery items. The consistency of thickness across the entire roll is vital to prevent defects during the thermoforming process. Hengjiang’s advanced manufacturing technology guarantees uniform caliper control in their pet sheet rolls, ensuring reliable performance on high speed forming lines and a consistent feel in the final custom packaging.

Selection Criteria for Specific Custom Applications

The application dictates the required specifications. Choosing the ideal pet sheet roll involves aligning its properties with the unique challenges of the product it will protect.

For High Clarity Fresh Food Packaging

When the goal is to showcase the freshness and quality of items like red meat, fresh pasta, or delicate pastries, the priority is supreme clarity and a high gloss finish. In this case, a premium APET sheet roll with exceptional optical properties is ideal. It should be free from haze, yellowing, or imperfections. The material must also have good inherent stiffness to create a tray that feels substantial. Sourcing from a manufacturer like Hengjiang, which operates a GMP standard clean workshop, ensures the pet sheet roll is produced in a contaminant free environment, preserving its pristine clarity and food safety from the very first stage of production.

For Dual Ovenable and Freezer Safe Packaging

For custom packaging that needs to go from freezer to microwave or conventional oven, CPET is the material of choice. The ideal pet sheet roll for this application must have the correct crystalline structure to provide thermal stability up to 220°C without warping or deforming. It requires specific processing during sheeting to achieve this property. Hengjiang’s expertise in food packaging, supported by a dedicated team of technical managers, allows them to produce CPET sheet rolls that reliably meet these demanding thermal performance standards, enabling the creation of convenient and safe meal solutions.

The Role of Advanced Manufacturing in Sheet Quality

The quality of the final custom package is inextricably linked to the quality of the pet sheet roll, which in turn depends entirely on the sophistication and control of the manufacturing process.

Precision in Sheet Extrusion

The process of creating a pet sheet roll involves melting PET resin and extruding it into a flat sheet of precise thickness, which is then cooled and wound onto rolls. Precision in temperature control, extrusion speed, and cooling is paramount to achieve consistent molecular orientation and physical properties. Variations can lead to issues like poor forming performance or weak spots in the final tray. Hengjiang’s investment in automated, state of the art PET sheet making lines provides this critical precision, resulting in pet sheet rolls that offer predictable, high quality performance for their clients’ custom packaging projects.

Integrated Quality Assurance

Superior manufacturing includes rigorous, in process quality checks. This involves monitoring for thickness variations, optical clarity, and surface defects. A manufacturer with an integrated laboratory can perform more advanced tests, such as measuring the intrinsic viscosity of the PET or testing barrier properties. Hengjiang’s 200 square meter laboratory facility allows for this level of quality validation. By testing their pet sheet rolls internally, they ensure that every roll shipped from their Zhejiang production base meets stringent specifications for custom food packaging applications.

Partnering with a Supplier for Custom Success

Choosing a supplier for pet sheet rolls is a strategic partnership. The supplier’s capabilities extend beyond simply providing material; they enable the entire custom packaging endeavor.

Technical Collaboration and Support

Developing successful custom packaging often requires collaboration. An ideal supplier offers technical expertise to help select the most suitable pet sheet roll grade, thickness, and size for the specific forming equipment and end use. With 10 dedicated technical managers, Hengjiang provides this essential support. Their team can assist in troubleshooting, optimizing designs for manufacturability, and ensuring the selected pet sheet roll will perform flawlessly when formed into the desired clamshell, tray, or container for products ranging from meats to artisan cakes.

Scale, Consistency, and Supply Chain Reliability

For a custom packaging project to be commercially viable, the supply of raw material must be reliable and scalable. Inconsistencies in the pet sheet roll can cause massive disruptions on the production line. A supplier with large scale, automated production ensures batch to batch uniformity. Hengjiang’s significant operational scale, with a 13,000 square meter facility and large storage capacity, guarantees they can deliver consistent, high quality pet sheet rolls in the volumes required, providing a stable foundation for their clients’ packaging operations.

Making the Final Decision for Your Brand

Selecting the ideal pet sheet roll is a balance of science, application knowledge, and strategic sourcing.

Evaluating Total Value Over Unit Cost

While price per kilogram is a factor, the total value of the pet sheet roll encompasses its yield (how many trays per roll), its performance on the forming line (reducing waste and downtime), and the quality it imparts to the final package (enhancing brand perception). A premium pet sheet roll from a certified manufacturer like Hengjiang often delivers a lower total cost of ownership by maximizing efficiency and end product quality.

Future Proofing with a Sustainable Mindset

The packaging industry is increasingly focused on sustainability. The ideal pet sheet roll today may also need to consider recycled content. Options like rolls containing post consumer recycled PET (rPET) are growing in demand. Forward thinking suppliers are developing these sustainable material solutions. Partnering with a manufacturer like Hengjiang, which is invested in advanced material technology, positions a brand to adapt to these evolving market demands for eco conscious custom packaging.

In conclusion, identifying the ideal pet sheet roll for custom packaging requires a detailed analysis of material grade, thickness, and application specific performance needs. It also demands a partnership with a manufacturer whose capabilities in precision production, quality assurance, and technical support can transform raw material into a successful packaging solution. Hengjiang, with its integrated manufacturing base in Zhejiang, China, exemplifies such a partner. Their commitment to producing pet sheet rolls in a GMP compliant cleanroom environment, validated through their own laboratory and supported by deep technical expertise, provides brands with a reliable and high quality foundation. By leveraging Hengjiang’s strengths in material science and large scale production, businesses can confidently select and utilize pet sheet rolls that bring their custom packaging designs to life, ensuring product protection, consumer appeal, and market success.