Understanding Food Safe vs. Food Grade Plastics in Meat Packaging

The critical difference between food safe and food grade plastics

Plastics labeled as food grade generally satisfy the minimum requirements set by the FDA when they come into contact with food accidentally. Food safe materials go through much stricter tests though, especially regarding how they hold up under different temperatures and whether they might leak chemicals over time. The FDA actually draws an interesting comparison in their guidelines about plastic that touches food items. Think of it kind of like shapes in geometry where all squares are rectangles but not all rectangles are squares. Every material that's considered food safe automatically qualifies as food grade too, although the reverse isn't true at all. Take those common meat trays made from polypropylene (number 5 on recycling labels). They're definitely food grade, but they won't earn the food safe designation unless they can survive being microwaved multiple times without giving off anything bad for our health.

FDA approval and compliance for food contact plastics: What it means for plastic meat trays

The FDA evaluates plastics under specific use conditions, approving materials like HDPE and PP for meat packaging when manufacturers follow processing guidelines. These resins must maintain structural integrity between -40°F and 120°F to prevent bacterial contamination and chemical migration.

How regulatory standards ensure the safety of plastic meat trays

Global standards like EU 10/2011 and FDA 21 CFR require third-party testing for heavy metals, phthalates, and endocrine disruptors. Compliance ensures that even thin-walled plastic meat trays prevent oxygen exposure without leaching plasticizers into fatty proteins like ground beef.

Top FDA Approved Plastics Used in Safe Plastic Meat Trays

HDPE : High density polyethylene for durable, safe meat storage

When it comes to plastic meat trays, HDPE or High-Density Polyethylene has become the go-to material thanks to how tough it is and because it meets all those FDA requirements. The #2 resin stands up pretty well against bumps and bruises during shipping, which means less product damage. Plus, it keeps meats from drying out faster than other plastics on the market. What really matters though is that HDPE doesn't absorb anything since its surface is completely smooth. This makes it much harder for bacteria to stick around, so it works great for packing raw meat whether at grocery stores or big distribution centers where hygiene standards need to be rock solid.

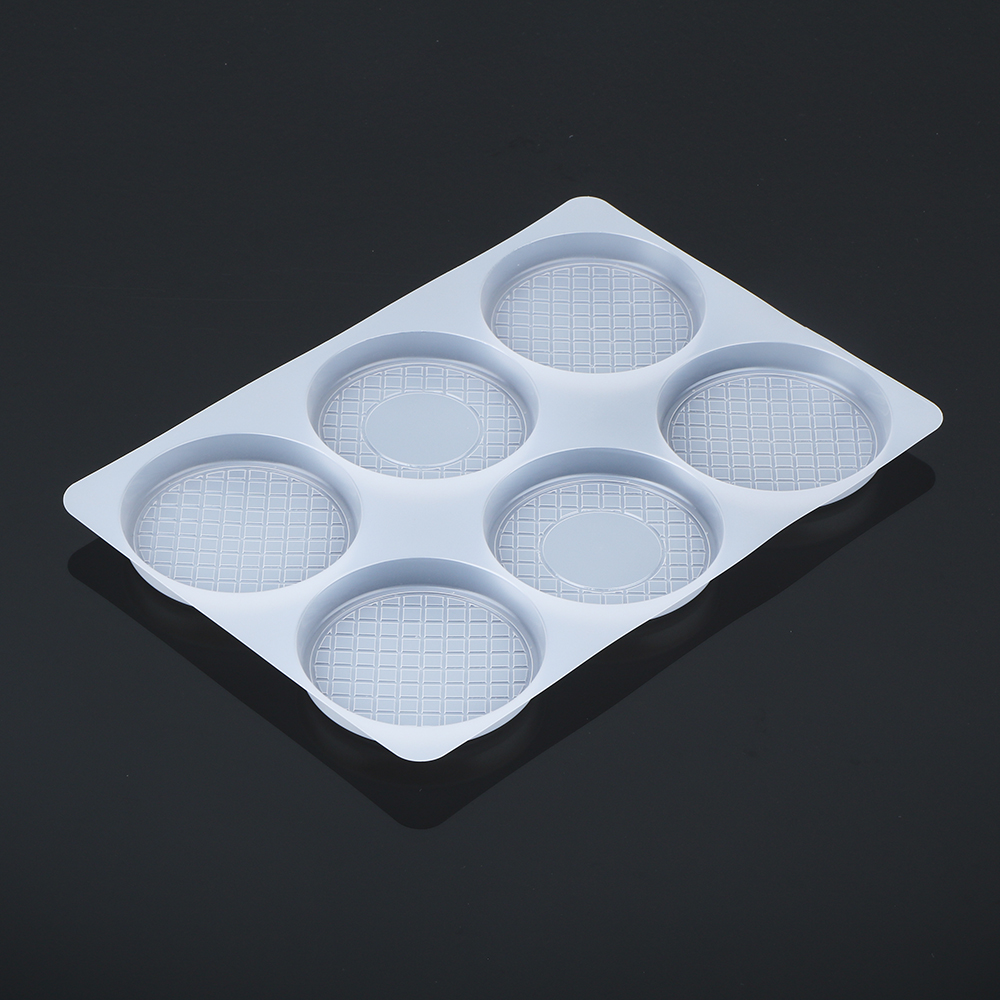

Polypropylene: Heat resistant plastic ideal for chilled and reheated meat trays

What makes polypropylene stand out is how stable it stays when exposed to heat. These plastic trays can handle temps as low as minus four degrees Fahrenheit all the way up to boiling water temperature without bending shape or releasing harmful substances into food. Food processors love this because they can actually put the same container through multiple stages of handling meat products. Frozen storage first, then letting things thaw naturally, and finally popping them into the microwave for reheating works just fine. Some recent tests on packaging materials found that these PP containers keep their strength after going through over five hundred freeze-thaw cycles. That means fewer replacements needed in busy restaurant back kitchens where waste management is always a concern.

LDPE and PET: Common yet compliant materials in meat packaging

While less rigid than HDPE or PP, these resins still meet FDA food-contact requirements:

- LDPE : Used for vacuum-sealed tray liners due to superior flexibility

- PET: Preferred for pre-cooked meat trays needing crystal-clear visibility

Both materials cost 18–22% less than premium resins but require careful thickness calibration to prevent punctures from bones or sharp meat edges.

Comparative safety and performance of food grade plastics for meat trays

| Factor | HDPE | PP | LDPE | PET |

|---|---|---|---|---|

| Max Temp | 160°F | 212°F | 140°F | 120°F |

| Reusability | 85 cycles | 200+ | 40 | 15 |

| Leaching Risk | Low | Low | Medium | High* |

PET shows increased chemical migration when exposed to acidic marinades or high-fat meats. Food engineers recommend HDPE and PP for extended storage, reserving LDPE/PET for short-term retail displays.

Decoding Plastic Recycling Codes for Meat Tray Safety

What Recycling Codes Mean for Food Safety in Plastic Meat Trays

Those little triangles we see on plastic meat trays, numbered from 1 all the way to 7, actually serve as kind of a safety code system. Each number tells us what kind of plastic was used and whether it's safe for contact with food stuffs. For instance, materials that meet FDA standards such as HDPE (number 2), LDPE (number 4), and PP (number 5) go through extensive tests to check if chemicals might migrate out of them. Scientists run these plastics through something called gas chromatography to make sure they stay within strict limits for things like heavy metals which need to be below 0.1 parts per million, plus they also test for plasticizers that could potentially leach into our food over time.

| Recycling Code | Material | Meat Tray Safety | Common Uses |

|---|---|---|---|

| #1 | PET | Limited* | Pre-packaged deli meats |

| #2 | HDPE | Safe | Raw meat storage containers |

| #3 | PVC | Unsafe | Avoid in all food contact |

| #5 | PP | Safe | Microwave-reheatable trays |

| #6 | Polystyrene | Unsafe | Foam packaging (banned in 12 states) |

*PET requires UV stabilizers for retail display check for BHT additives

Risks of PVC and Polystyrene in Direct Food Contact Applications

PVC trays containing DEHP plasticizers showed phthalate migration 34x above FDA limits in fatty meat simulations (USDA 2022). Polystyrene (#6) foam trays leach styrene monomers when contacting acidic marinades a 2021 study linked prolonged exposure to 50% higher lymphoma risks in animal models.

Are Recycled Plastics Safe for Food Grade Meat Trays? Industry Debate

While 72% of consumers demand recycled packaging, current FDA rules prohibit post-consumer recycled plastics in direct meat contact. Advanced recycling technologies like depolymerization can create virgin-grade rPET, but only 12% of U.S. recycling facilities meet 2024 purity standards for food-grade reuse.

BPA, Chemical Leaching, and Health Risks in Plastic Meat Trays

Do Plastic Meat Trays Contain BPA? Understanding Chemical Leaching Risks

Most plastic meat trays on store shelves today advertise themselves as BPA free, but research shows we still have problems with chemicals seeping into our food from packaging. Recent tests looked at meat containers last year and discovered traces of BPA in about one out of every five samples tested. What's worse, manufacturers often replace BPA with alternatives such as BPS or BPF which aren't much better for our hormones. These substances actually find their way into meats including beef and chicken during normal fridge storage conditions. According to findings published by Montana Ranch in their latest food safety report, migration rates reach around 2.3 micrograms per kilogram in some cases. That might not sound like much, but when multiplied across all the packaged meats people consume regularly, it adds up pretty quickly.

The FDA prohibits BPA in baby bottles but maintains a 5 ppm tolerance for adult food contact plastics—a threshold critics argue fails to account for cumulative exposure from meat trays, canned foods, and bottled beverages.

How Temperature Impacts Chemical Migration from Plastic to Meat

Heat accelerates molecular interactions between plastics and meat, increasing chemical migration rates by 5–7x compared to room-temperature storage (University of California 2023). Defrosting frozen meat in its original tray at 140°F caused:

| Scenario | BPA Leaching Rate | Health Impact Threshold* |

|---|---|---|

| Refrigeration (40°F) | 0.8 µg/kg | 25% of safety limit |

| Microwave reheating (160°F) | 4.6 µg/kg | 117% of safety limit |

Based on 0.05 mg/kg/day EPA reference dose

This thermal vulnerability is why hospitals and schools increasingly ban PVC and polystyrene trays in favor of polypropylene alternatives.

Balancing Cost Effective Materials with Long-Term Consumer Health

Manufacturers face pressure to balance $0.12–$0.18 per-unit savings from PVC trays against potential liabilities from hormone disruption claims. Emerging solutions include:

- Plant-based PLA liners reducing BPA migration by 89%

- Active packaging with oxygen scavengers to limit chemical reactions

- Time-temperature indicators alerting staff to thermal abuse

While no plastic meat tray achieves zero chemical transfer, prioritizing #2 HDPE and #5 PP trays significantly lowers risks compared to economy-grade options.

Heat Resistance and Structural Integrity of Food Grade Meat Trays

Evaluating Heat Resistance in Real World Meat Storage and Transport

Meat packaging trays made from food grade plastics need to handle quite a temperature range actually ranging from super cold storage at minus 40 degrees Fahrenheit all the way up to reheating at around 250 degrees. While polypropylene or PP number 5 holds up pretty well for quick microwave sessions, the industry has found something interesting about PET trays labeled as number 1. These tend to warp about two and a half times quicker than PP when they get hit with steam heat. Looking at freezer performance though, HDPE number 2 stands out among competitors. This material shows remarkable resistance to cracking even after going through thirty complete freeze thaw cycles according to the latest Food Packaging Safety Report published in 2025. That kind of durability makes it a top choice for frozen food applications where reliability matters most.

Safe Plastic Containers for Refrigerated and Temperature Variable Conditions

When dealing with cold chain logistics, HDPE materials can handle temperatures down to around -76 degrees Fahrenheit without cracking during those freezing transport conditions. Containers made from dual certified polypropylene work well when moving items between fridge storage at about 34 degrees and then heating them in ovens up to 200 degrees without any harmful substances leaking out. Fatty meats should definitely not go into LDPE plastic marked with the number 4 recycling symbol though. These plastics have a lower density that lets chemicals migrate through the material at a rate 18 percent higher when exposed to temperature changes above 140 degrees according to research published last year in the Journal of Food Science.

When Plastic Meat Trays Fail: Thermal Stress and Container Integrity

Repeated thermal cycling causes 67% of tray failures, with PET developing microfractures after just 5 freezer-to-oven transitions. High-heat scenarios (>300°F) can warp even PP trays, compromising seal integrity and increasing bacterial contamination risks by 40% (Food Protection Trends 2025). Always verify tray thickness—0.8mm minimum for roasted meats vs. 0.5mm for chilled cuts.

FAQ

What is the difference between food-safe and food-grade plastics?

Food-grade plastics meet the basic FDA requirements for accidental food contact, while food-safe plastics undergo more rigorous testing, including temperature resistance and chemical leakage checks. Thus, food-safe materials are always food-grade, but not all food-grade materials are food-safe.

What plastics are considered safe for meat packaging?

According to the FDA, plastics like HDPE (#2), LDPE (#4), and PP (#5) are considered safe for meat packaging, provided they meet specific processing guidelines.

Why are some plastics unsuitable for food contact?

Certain plastics like PVC (#3) and polystyrene (#6) can leach harmful chemicals into food, making them unsafe for direct food contact applications.

Are there differences in recycling codes on meat trays?

Yes, recycling codes indicate the type of plastic and its safety level for food contact. Codes like #2 (HDPE) and #5 (PP) are generally considered safe for food, while #3 (PVC) and #6 (polystyrene) are not recommended.

Do plastic meat trays contain BPA?

Although many meat trays are labeled BPA-free, they may still contain BPA alternatives like BPS or BPF, which can also pose health risks.

Table of Contents

- Understanding Food Safe vs. Food Grade Plastics in Meat Packaging

- Top FDA Approved Plastics Used in Safe Plastic Meat Trays

- Decoding Plastic Recycling Codes for Meat Tray Safety

- BPA, Chemical Leaching, and Health Risks in Plastic Meat Trays

- Heat Resistance and Structural Integrity of Food Grade Meat Trays

- FAQ